Single Screw Extruder Machine

High-performance plastic extrusion systems for pipes, sheets, profiles, and recycling. New and pre-owned machines with inspection support and India-ready compatibility.

Why Choose Single Screw Extruder?

The preferred choice for plastic extrusion and recycling lines across industries worldwide.

Stable & Continuous Output

Consistent product quality with reliable continuous operation for high-volume production.

High Plasticizing Efficiency

Uniform melt temperature across the barrel ensures excellent material homogenization.

Easy Operation & Maintenance

Simpler mechanism compared to twin-screw systems with readily available spare parts.

Wide Material Compatibility

Process PE, PP, PVC, ABS, PS, PET, and recycled plastics with proper screw configuration.

Cost-Effective Solution

Lower capital investment and maintenance costs ideal for SMEs and large manufacturers.

Proven Technology

Industry-standard design with decades of refinement and global manufacturer support.

Versatile Industrial Applications

Single screw extruders serve diverse industries from packaging to construction and recycling.

Plastic Pipe Extrusion

Water supply, drainage, and industrial piping systems

Sheet & Board Production

Packaging, signage, and construction sheets

Profile Extrusion

Window frames, channels, trims, and custom profiles

Film & Lamination

Agricultural films, packaging, and lamination layers

Cable Coating

Wire insulation and protective cable sheathing

Recycling & Re-pelletizing

Converting plastic waste into reusable granules

*Material compatibility depends on screw design and heating configuration.

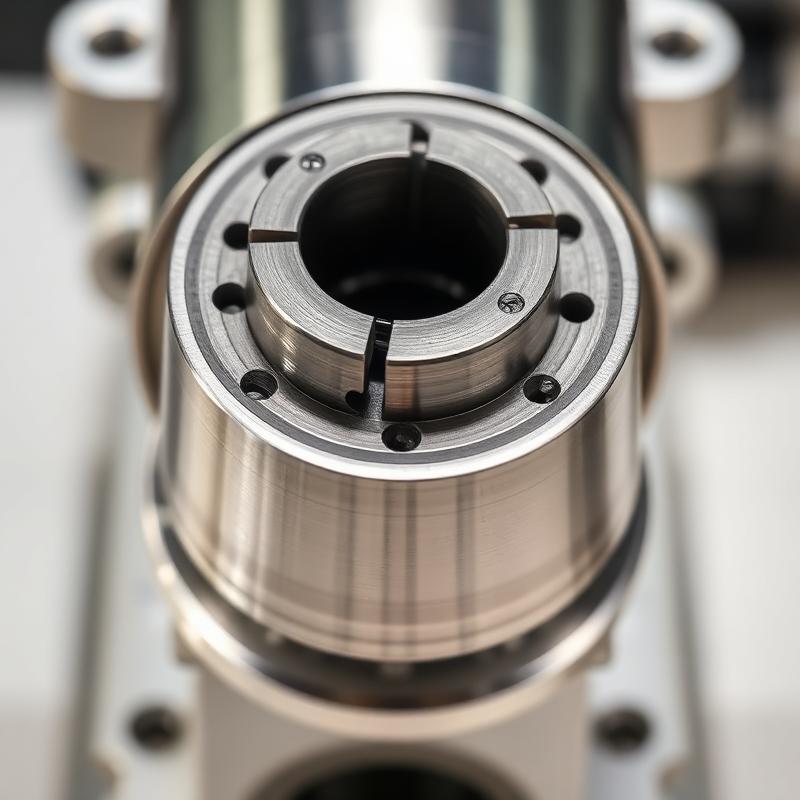

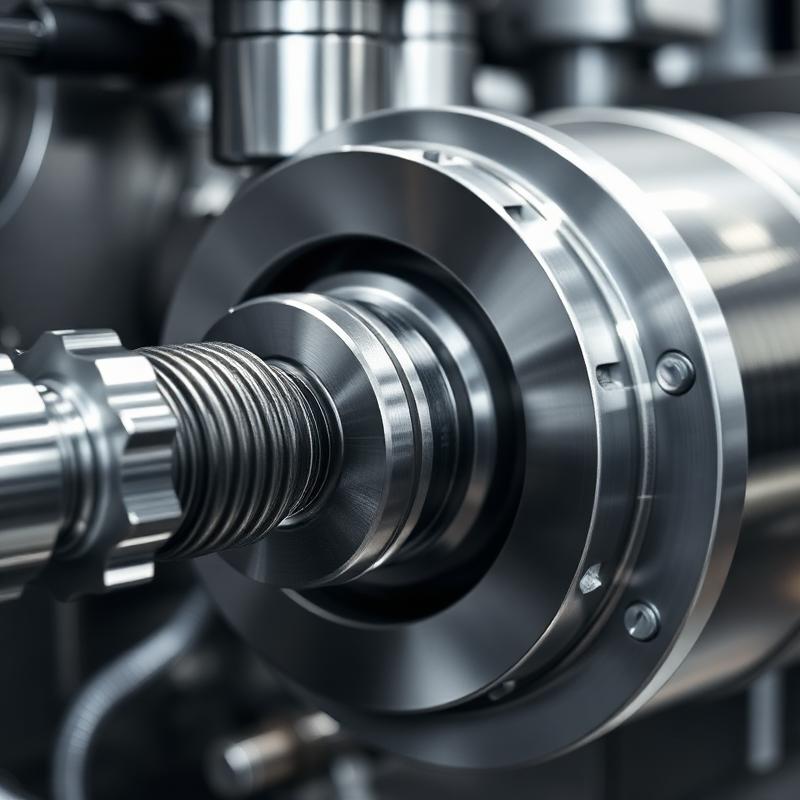

Machine Details & Components

Explore every angle of our single screw extruder machines. Click any image to zoom in.

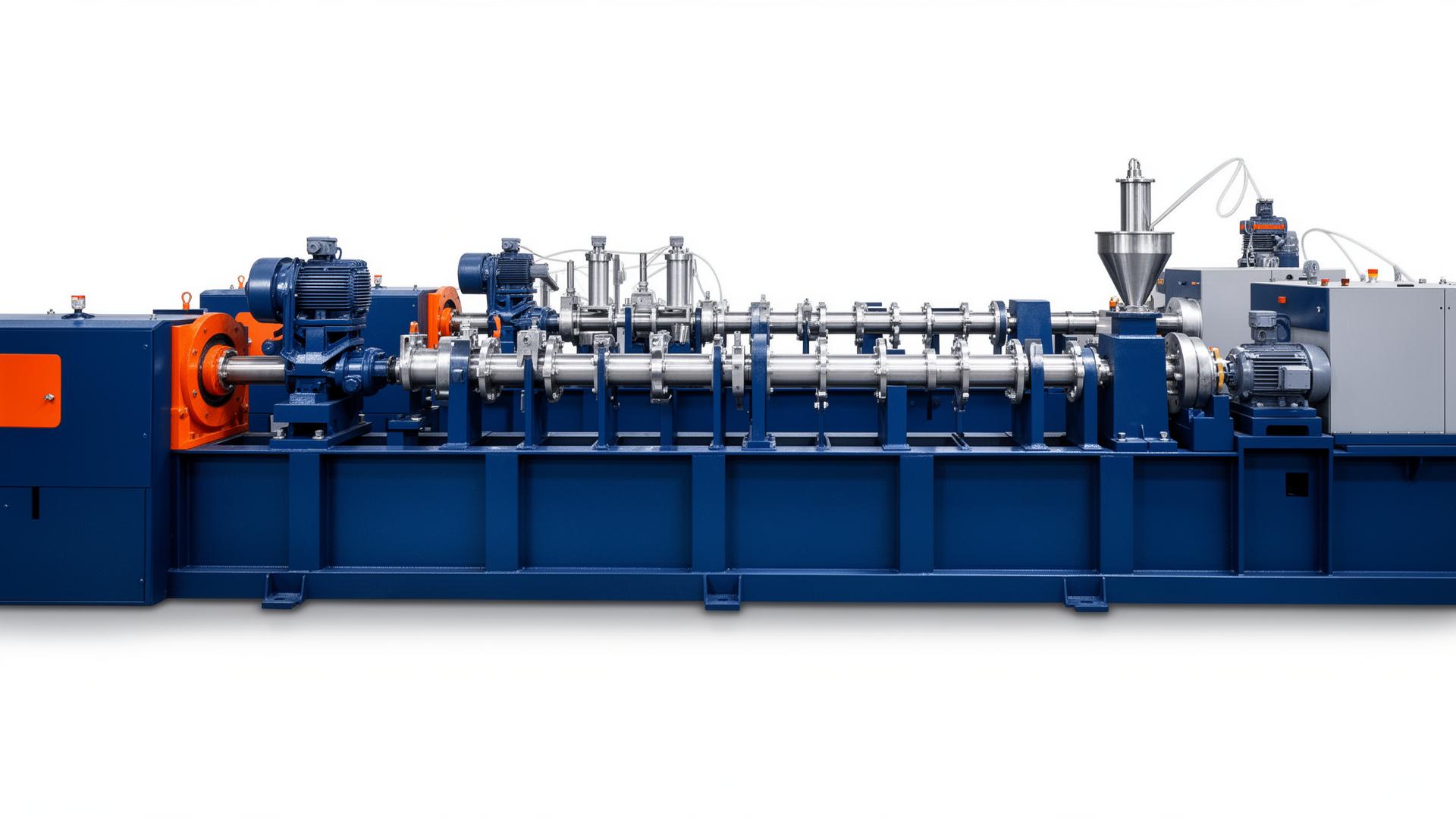

Complete Machine

Full single screw extruder line with barrel, gearbox, and controls

Front View

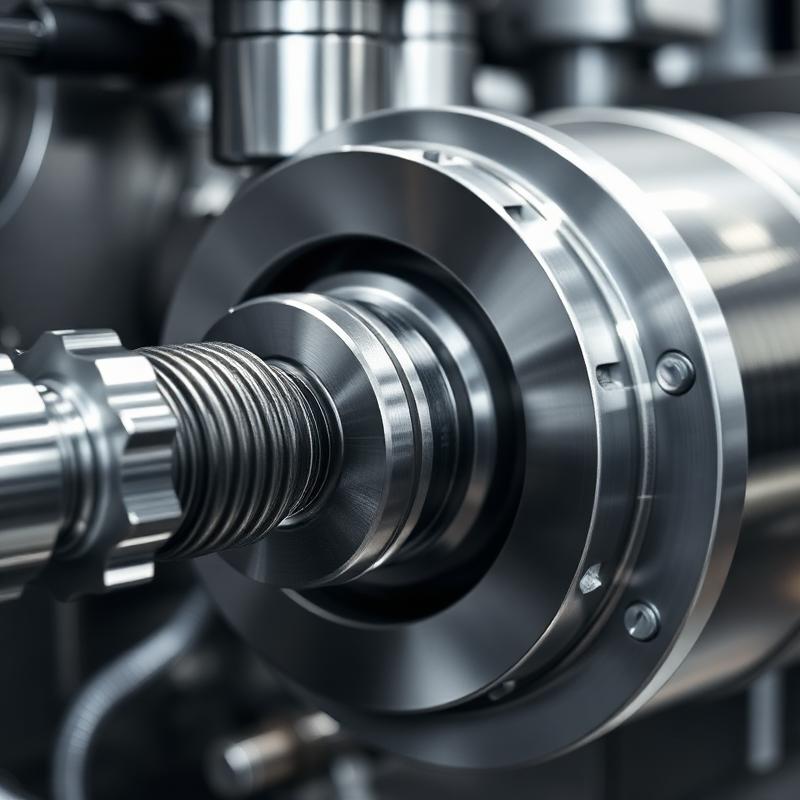

Screw & Barrel

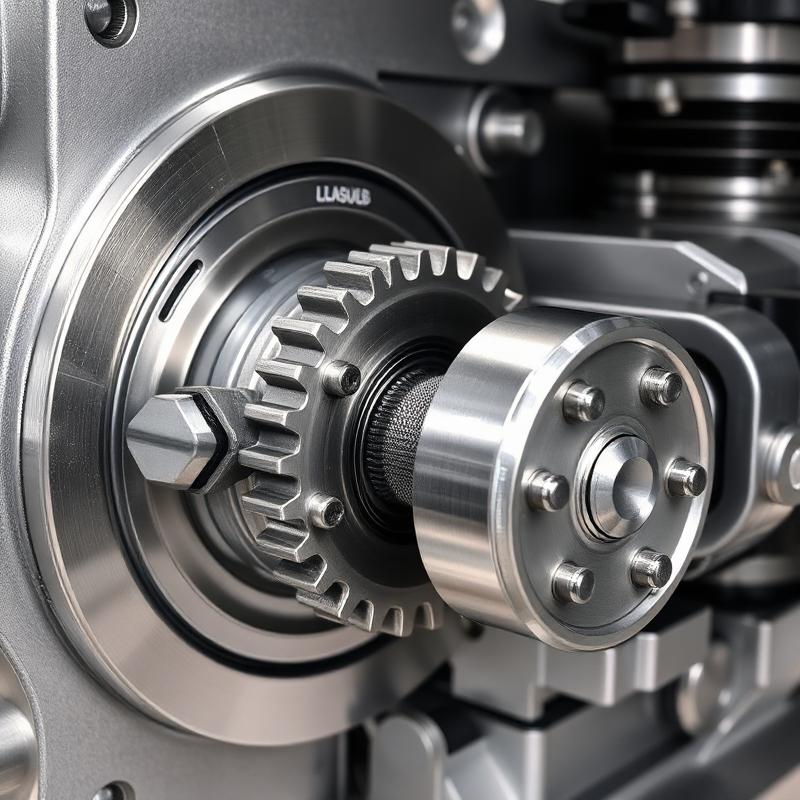

Gearbox Assembly

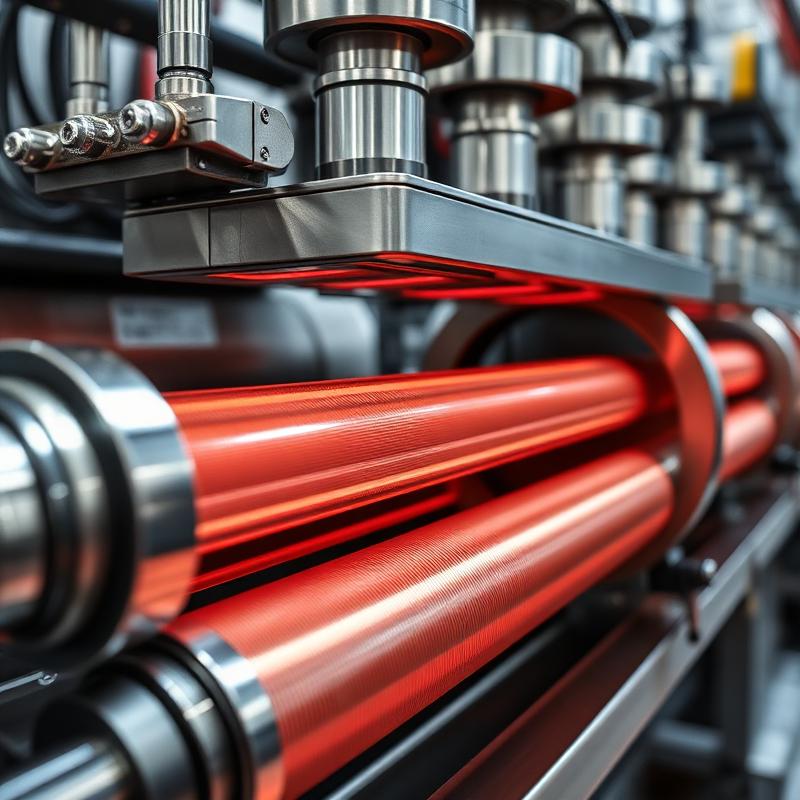

Heating System

Control Panel

Die Head

Technical Specifications

Final specifications depend on model size (SJ-25 to SJ-150 or equivalent) and application requirements. Contact us for detailed specifications matching your production needs.

| Parameter | Specification |

|---|---|

| Screw Diameter | 25 mm – 150 mm |

| L/D Ratio | 25:1 – 33:1 |

| Screw Type | Nitrided / Bimetallic (optional) |

| Output Capacity | 20 – 800 kg/hr |

| Extrusion Material | PE, PP, PVC*, ABS, PS, PET*, Recycled plastics |

| Control System | PLC + HMI / Digital PID |

| Cooling System | Air / Water cooling |

| Mounting | Floor mounted |

| Parameter | Specification |

|---|---|

| Main Motor Power | 7.5 – 250 kW |

| Drive Type | AC Motor with VFD |

| Gearbox | Hardened helical / thrust bearing gearbox |

| Power Supply | 3 Phase, 380–415V, 50Hz |

| Parameter | Specification |

|---|---|

| Heating Zones | 3 – 10 zones |

| Heater Type | Ceramic / Cast aluminum |

| Temperature Control Accuracy | ±1°C |

| Max Barrel Temperature | Up to 350°C |

| Parameter | Specification |

|---|---|

| Barrel Material | Alloy steel, nitrided |

| Screw Hardness | ≥ HV900 (nitrided) |

| Frame | Heavy-duty welded steel |

| Noise Level | ≤ 85 dB |

| Operation Mode | Continuous |

Optional Equipment

Complete your extrusion line with our range of auxiliary equipment.

Quality Assurance

Pre-owned machine inspection and verification services.

Installation & Support

End-to-end support from shipping to commissioning.

Ready to Upgrade Your Extrusion Line?

Get expert advice on selecting the right single screw extruder for your production needs. New and pre-owned options available with inspection support.