Conical Twin Screw Plastic Extruder Machine

High-performance extrusion system for PVC pipe, profile, sheet, and board production. Ideal for heat-sensitive materials with superior mixing and low shear heat generation.

Key Advantages

Discover why conical twin screw extruders are the industry standard for PVC extrusion lines

Excellent PVC Processing

Optimized for PVC and heat-sensitive plastic materials with consistent quality output.

Low Shear & Heat

Minimal heat generation protects material integrity, ideal for heat-sensitive compounds.

High Output Capacity

Stable melt pressure ensures high throughput from 60 to 1200 kg/hr depending on model.

Superior Mixing

Counter-rotating screws provide uniform plasticization and excellent material blending.

Energy Efficient

Advanced design reduces power consumption while maintaining peak performance.

Long Service Life

Hardened screw and barrel construction (≥HV900) ensures extended operational lifespan.

Applications

Conical twin screw extruders are versatile machines widely used across the PVC processing industry for various product types.

7+

Product Types

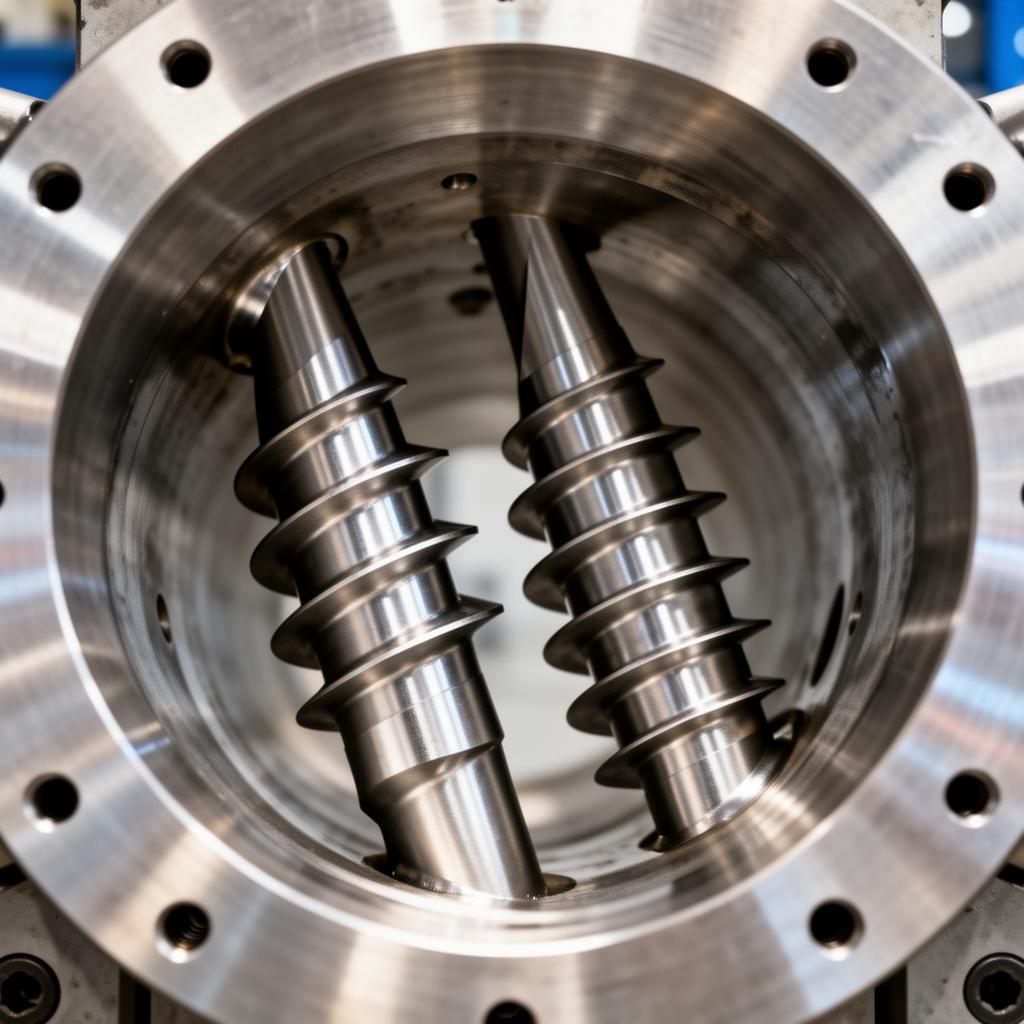

Working Principle

Understanding the counter-rotating conical twin screw extrusion process

Material Feeding

Raw material is fed into the hopper and conveyed forward with gradual compression.

Conical Screw Action

Two conical screws rotate in opposite directions, ensuring strong feeding capacity.

Melting & Mixing

Uniform melting and mixing at lower barrel temperatures for optimal material processing.

Extrusion & Shaping

Molten material is shaped through a die and cooled using downstream equipment.

Counter-rotating conical twin screws provide superior mixing

Technical Specifications

Detailed specifications for models SJSZ-51 / 55 / 65 / 80 / 92

| Parameter | Specification |

|---|---|

| Screw Type | Conical, counter-rotating twin screw |

| Screw Diameter | 45/90 mm – 80/156 mm |

| L/D Ratio | 22:1 – 28:1 |

| Output Capacity | 60 – 1200 kg/hr |

| Processing Material | PVC, PVC-U, PVC-C, WPC |

| Control System | PLC + Touch Screen (HMI) |

| Cooling System | Air & water cooling |

| Operation | Continuous |

| Parameter | Specification |

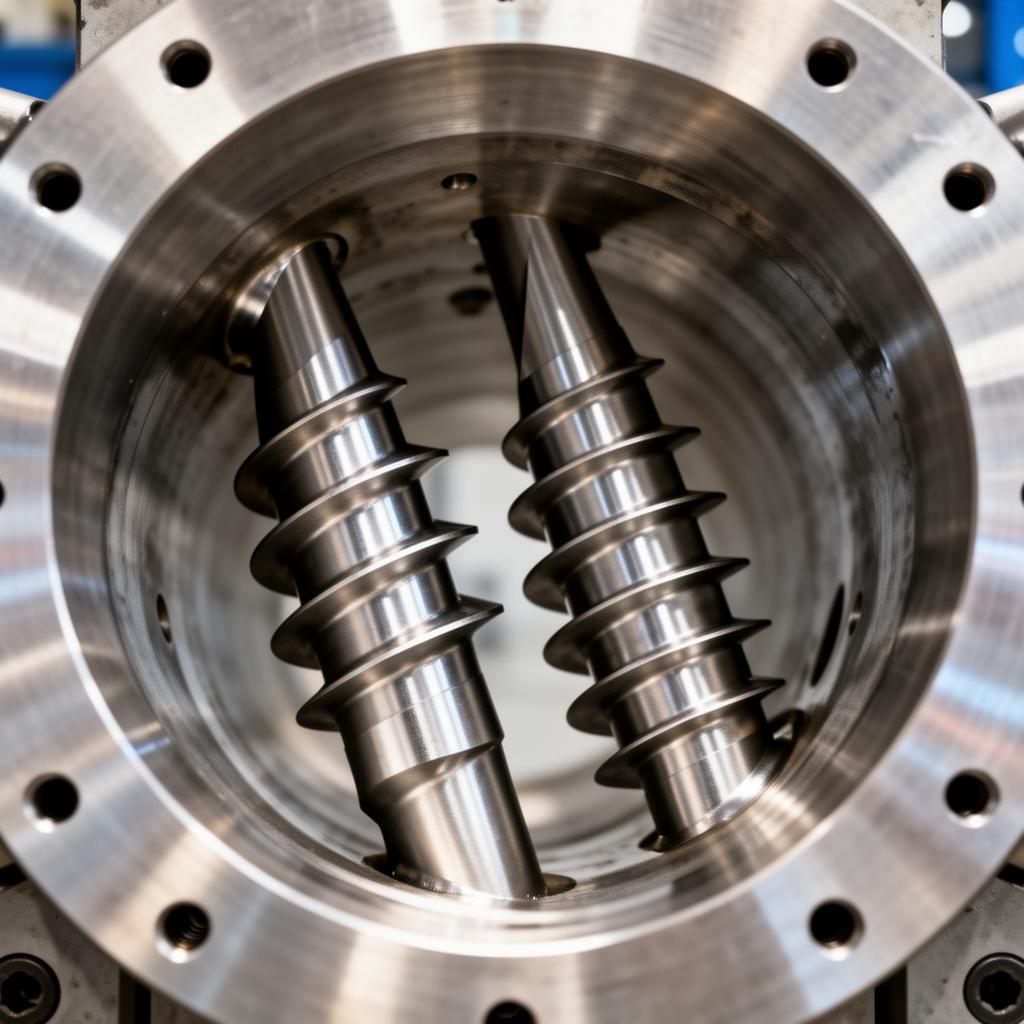

|---|---|

| Main Motor Power | 18.5 – 110 kW |

| Drive Type | AC Motor with VFD |

| Gearbox | High-torque hardened gearbox |

| Power Supply | 3 Phase, 380–415V, 50Hz |

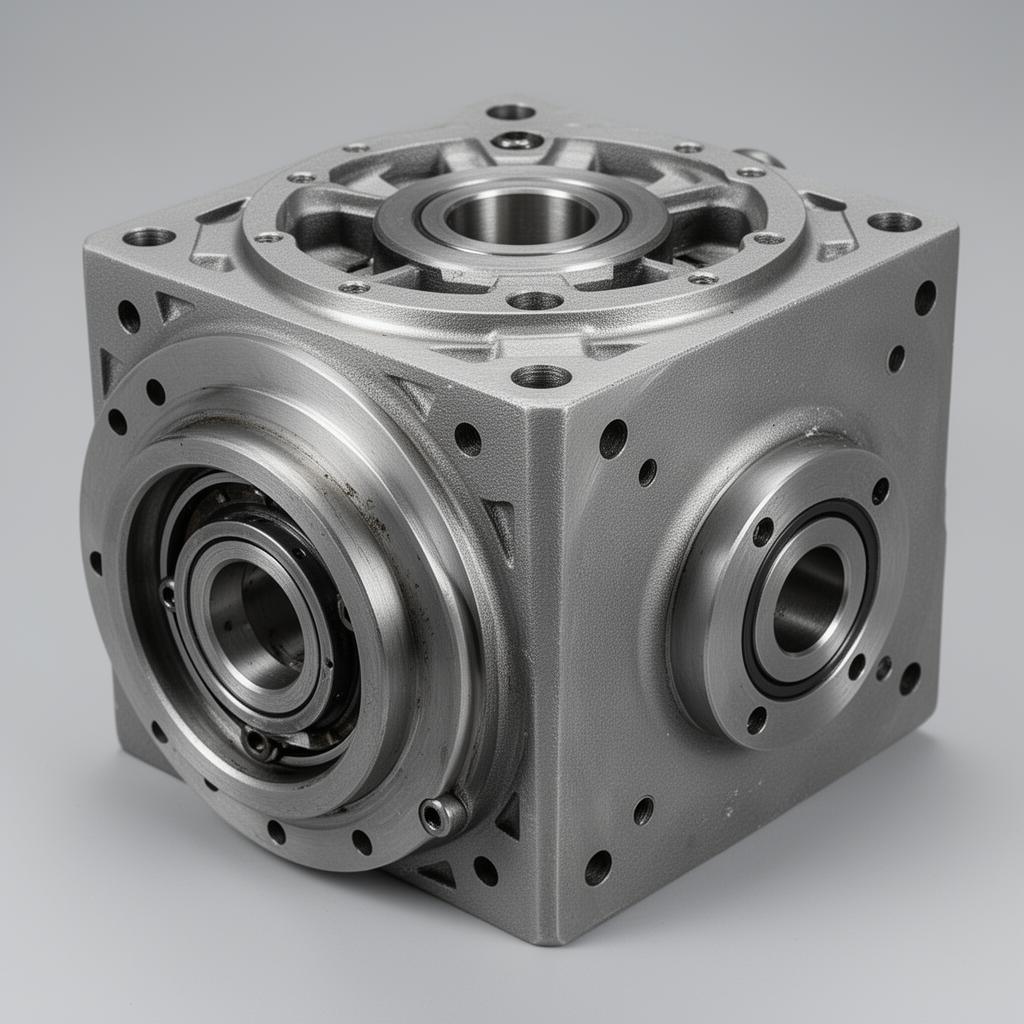

| Parameter | Specification |

|---|---|

| Heating Zones | 4 – 10 zones |

| Heater Type | Ceramic / Cast aluminum |

| Temperature Accuracy | ±1°C |

| Max Barrel Temperature | Up to 300°C |

| Parameter | Specification |

|---|---|

| Barrel Material | Nitrided alloy steel |

| Screw Surface Hardness | ≥ HV900 |

| Frame | Heavy welded steel |

| Noise Level | ≤ 85 dB |

| Mounting | Floor mounted |

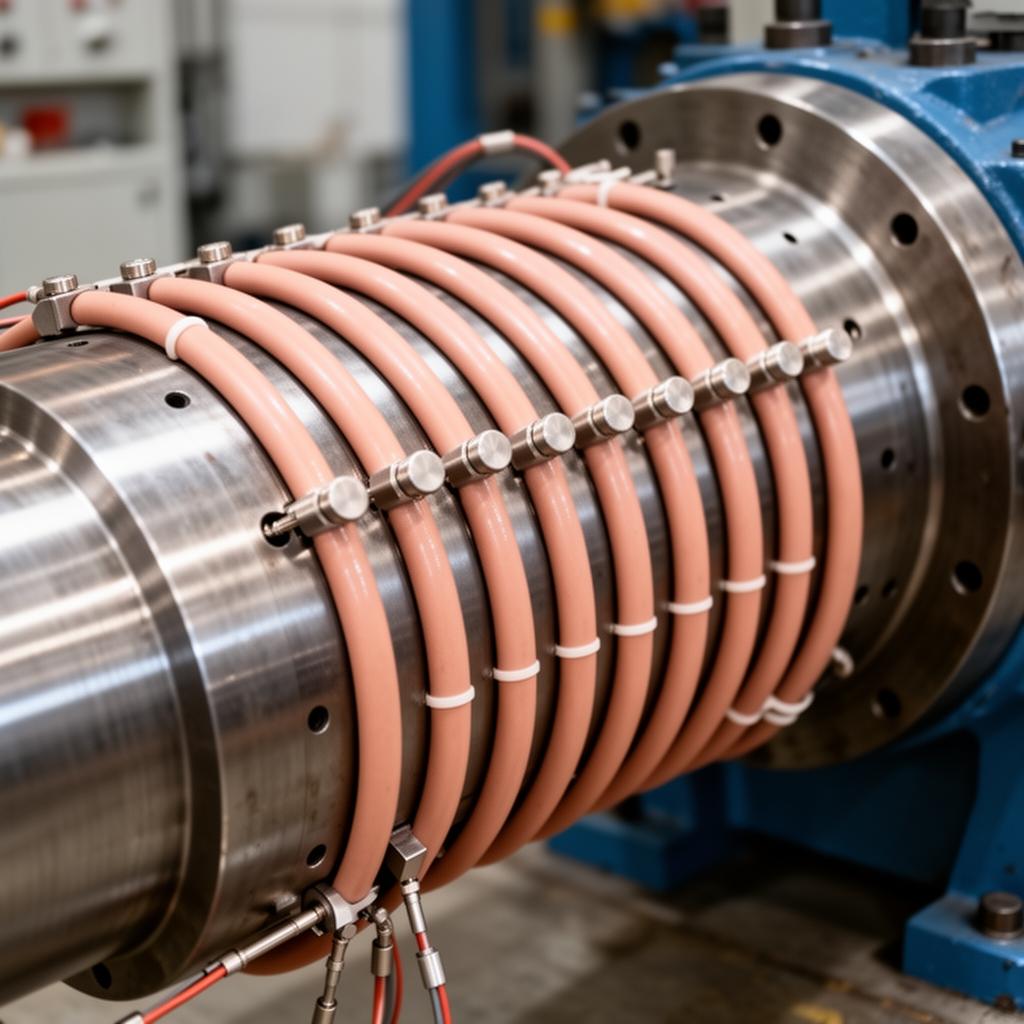

Machine Gallery

Explore detailed views of our conical twin screw extruder components, controls, and factory installations

Complete Extruder Machine

Full Machine

Complete Extruder Machine

Full Machine

Complete Extruder Machine

Full Machine

Complete Extruder Machine

Full Machine

Complete Extruder Machine

Full Machine

Complete Extruder Machine

Full Machine

Complete Extruder Machine

Full Machine

Complete Extruder Machine

Full Machine

Optional Accessories & Line Equipment

Complete your extrusion line with our range of auxiliary equipment

Automatic Vacuum Hopper Loader

Material Mixer & Dosing System

Hydraulic / Automatic Screen Changer

Vacuum Calibration Table

Cooling Tank

Haul-off Unit

Cutter / Saw / Stacker

PLC Recipe System

Online Thickness Control

Pre-Owned Machine Quality Assurance

For pre-owned conical twin screw extruders, SASA IMPEX provides comprehensive inspection and quality verification:

Installation & After-Sales Support

Export Packing

Container-ready packaging

Electrical Conversion

Indian standards (415V, 50Hz)

Installation Support

Commissioning assistance

Operator Training

Documentation & training