AC Waste ScrapRadiator SeparatorRecycling Machine

High-efficiency copper–aluminum radiator separator for car and HVAC radiator recycling. Recover high-value metals with 99%+ purity—no burning, no chemicals, no water.

Key Advantages

Our radiator separator machines deliver exceptional performance with minimal environmental impact

Clean Mechanical Separation

No burning, no pollution—environmentally friendly dry process

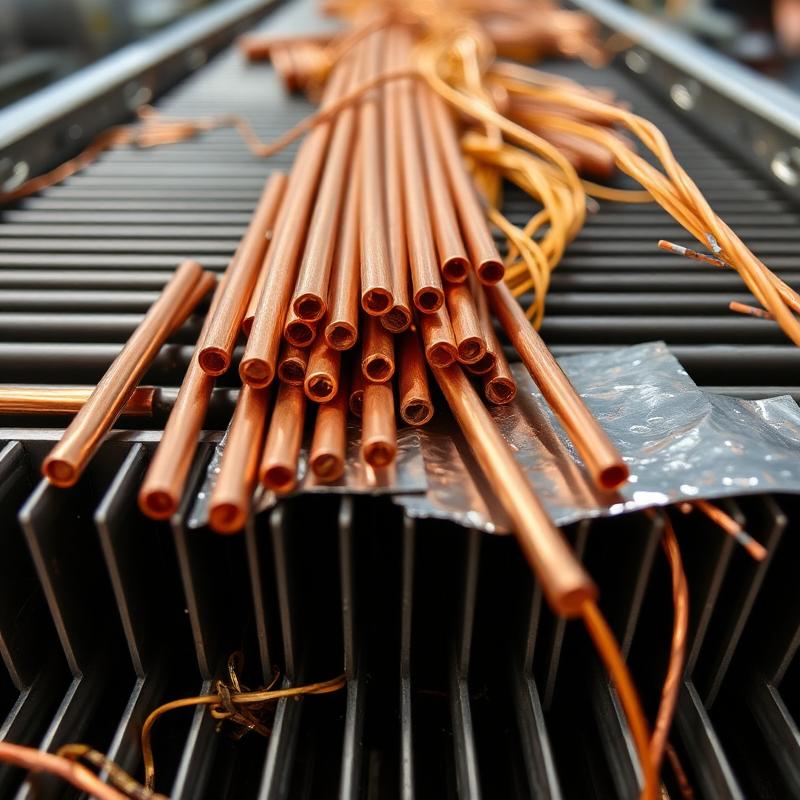

High Purity Output

Achieve ≥99% purity for both copper and aluminum separation

Zero Water Required

Completely dry process eliminates water usage and treatment costs

Compact & Efficient

Energy-efficient design with minimal footprint for any facility

Easy Operation

Simple controls with low manpower requirements

Fast ROI

Quick return on investment for scrap recycling businesses

Applications

Our radiator separator machine is suitable for recycling a wide range of copper-aluminum scrap materials from various industries.

Product Gallery

Explore our radiator separator machine from every angle—see the separation process, control systems, and high-purity output materials

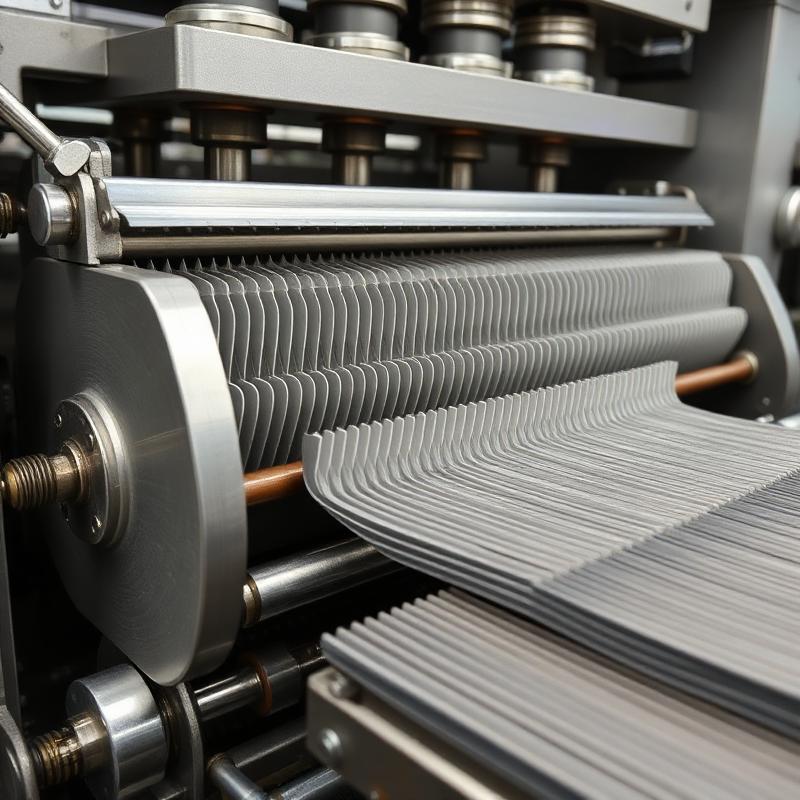

Complete Machine View

Full industrial radiator separator with feeding system and discharge outlets

Complete Machine View

Full industrial radiator separator with feeding system and discharge outlets

Complete Machine View

Full industrial radiator separator with feeding system and discharge outlets

Complete Machine View

Full industrial radiator separator with feeding system and discharge outlets

Complete Machine View

Full industrial radiator separator with feeding system and discharge outlets

Complete Machine View

Full industrial radiator separator with feeding system and discharge outlets

Working Principle

The process ensures maximum metal recovery with minimal material loss

Feeding

Radiators are manually or conveyor-fed into the machine

Cutting & Stripping

A cutting/stripping mechanism opens the aluminum fins

Separation

Rollers & blades separate copper tubes from aluminum sheets

Discharge

Separated materials are discharged independently

Collection

Dust is minimized through enclosed processing

Technical Specifications

Final specifications vary by model and radiator size

General Specifications

| Parameter | Specification |

|---|---|

| Machine Type | Copper–Aluminum Radiator Separator |

| Processing Method | Dry mechanical stripping |

| Raw Material | AC & car radiators |

| Separation Purity | ≥ 99% (Cu & Al) |

| Processing Capacity | 300 – 3000 kg/day |

| Operation Mode | Semi-automatic / Automatic |

| Control System | Electrical / PLC (optional) |

Power & Electrical

| Parameter | Specification |

|---|---|

| Main Motor Power | 4 – 22 kW |

| Voltage | 380–415 V |

| Frequency | 50 Hz |

| Phase | 3 Phase |

| Energy Consumption | Low |

Mechanical & Build

| Parameter | Specification |

|---|---|

| Blade Material | Alloy steel, heat-treated |

| Frame Construction | Heavy-duty welded steel |

| Noise Level | ≤ 85 dB |

| Water Requirement | Nil |

| Installation | Floor-mounted |

| Operation | Continuous |

Optional Add-Ons

Secondhand Machine Quality Assurance

For pre-owned radiator recycling machines, SASA IMPEX provides comprehensive quality checks:

Installation & After-Sales Support

Complete support from purchase to production:

Why Choose a Radiator Separator?

High-Value Metal Recovery

Converts HVAC & auto scrap into high-value copper and aluminum

Zero Pollution

No environmental pollution from burning or chemical processes

Simple Operation

Easy to operate with low running costs

Scalable Solution

Ideal for small to medium recycling units

Strong Market Demand

High demand for recovered copper & aluminum ensures profitability

Ready to Start Recycling?

Contact us today for pricing, availability, and technical consultation for your radiator recycling needs.