Blades, Dies & Moulds

Product Categories

Critical precision tooling components used across a wide range of industrial machines for cutting, shaping, forming, and mass production.

Industrial Blades

Used for cutting, shredding, granulating, and shearing operations.

Scrap shear blades

Shredder blades

Granulator & crusher blades

Slitting & rotary blades

Guillotine & paper cutting blades

Plastic recycling blades

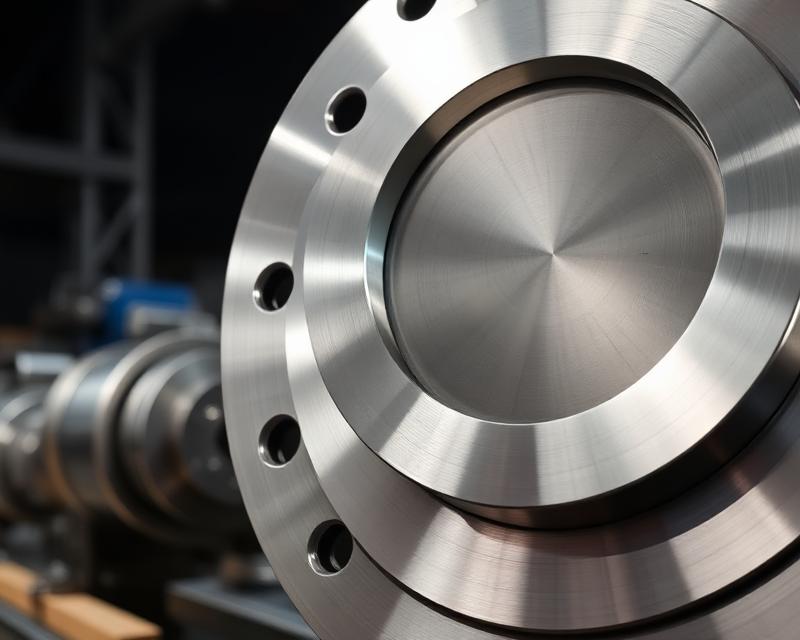

Industrial Dies

Precision tools used to shape or form materials under pressure.

Forging dies

Extrusion dies (pipe, profile, sheet)

Punch & press dies

Drawing dies

Trimming dies

Wire drawing & cable dies

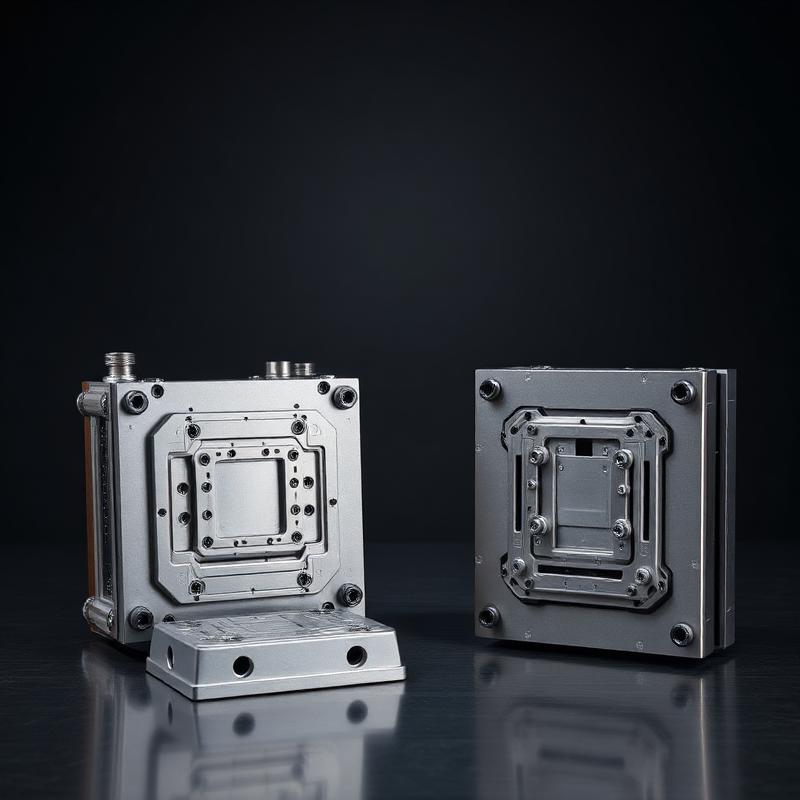

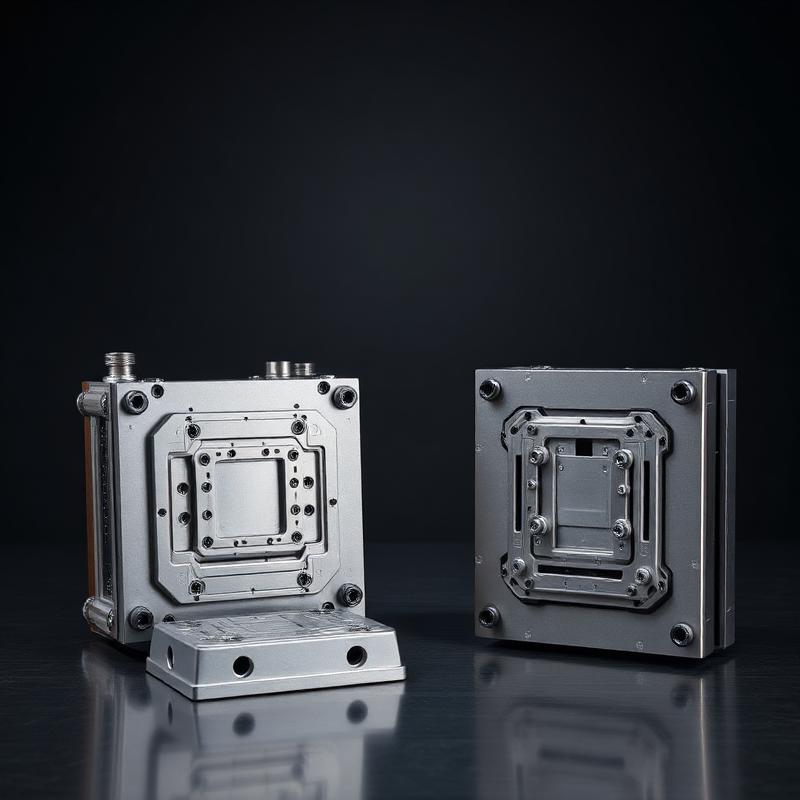

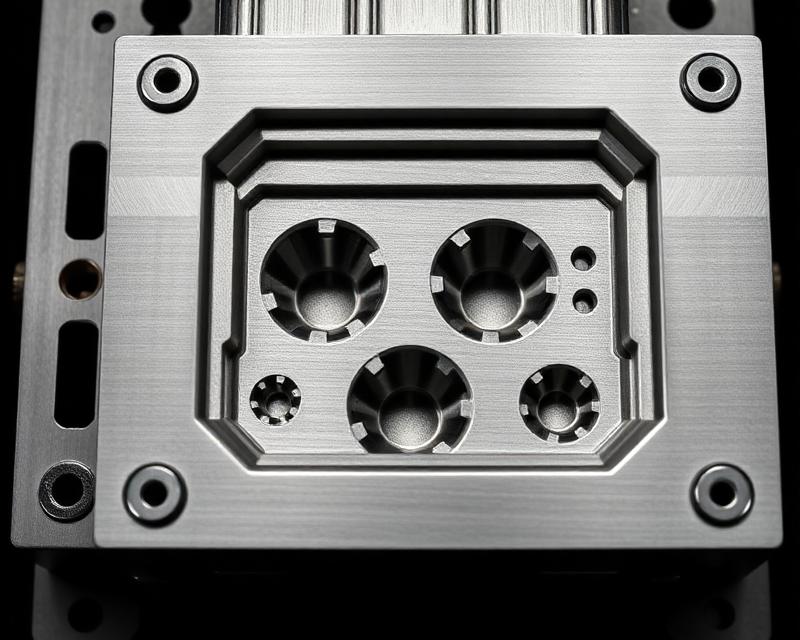

Industrial Moulds

Used in plastic, rubber, and metal forming processes.

Injection moulds

Blow moulds

Compression moulds

Rubber moulds

Die-casting moulds

Custom industrial moulds

Key Advantages

Our blades, dies, and moulds deliver exceptional performance that directly impacts product accuracy and production efficiency.

High Dimensional Accuracy

Precision-engineered to exact specifications for perfect fit and performance.

Long Service Life

Premium materials ensure extended tool life and reduced replacement costs.

Superior Surface Finish

High-quality surface treatment for optimal product output quality.

Reduced Downtime

Reliable performance minimizes production interruptions and delays.

Improved Consistency

Maintain uniform product quality throughout production runs.

Machine Compatible

Works seamlessly with both Indian and imported industrial machines.

Applications

Blades, dies, and moulds are widely used across diverse industrial sectors.

Metal Recycling & Scrap Processing

Shredding, cutting, and processing of metal scrap and recyclables.

Plastic Recycling & Extrusion

Granulating, shredding, and extruding plastic materials.

Injection & Blow Moulding

Precision moulds for plastic product manufacturing.

Forging & Press Shops

Heavy-duty dies for metal forming and forging operations.

Packaging & Paper Industries

Cutting and shaping tools for packaging production.

Automotive & Electrical

Specialized tooling for automotive and electrical components.

Technical Specifications

Specifications vary based on application, material, and machine compatibility.

| Parameter | Specification |

|---|---|

| Blade Type | Shear, shredder, granulator, rotary |

| Blade Material | D2, SKD11, H13, Cr12MoV |

| Hardness | 52 – 62 HRC |

| Blade Thickness | 10 – 200 mm |

| Blade Length | Up to 3000 mm |

| Surface Treatment | Heat-treated, nitrided (optional) |

| Parameter | Specification |

|---|---|

| Die Type | Forging, extrusion, press, trimming |

| Die Material | H13, H11, SKD61, P20 |

| Hardness | 40 – 58 HRC |

| Tolerance | ±0.01 – ±0.05 mm |

| Cooling System | Water / oil (if applicable) |

| Application | Hot & cold forming |

| Parameter | Specification |

|---|---|

| Mould Type | Injection, blow, compression |

| Mould Steel | P20, H13, S136, 718 |

| Cavity Options | 1 – 64 cavities |

| Mould Life | 300,000 – 2,000,000 shots |

| Runner System | Hot runner / Cold runner |

| Surface Finish | Mirror / Texture / EDM |

Product Gallery

Browse our extensive collection of precision-engineered blades, dies, and moulds for industrial applications.

Industrial Cutting Blades

Blades

Industrial Cutting Blades

Blades

Industrial Cutting Blades

Blades

Industrial Cutting Blades

Blades

Industrial Cutting Blades

Blades

Industrial Cutting Blades

Blades

Industrial Cutting Blades

Blades

Industrial Cutting Blades

Blades

Industrial Cutting Blades

BladesQuality & Secondhand Tooling Assurance

For pre-owned blades, dies, and moulds, SASA IMPEX provides comprehensive quality assurance to ensure reliable performance and value for your investment.

Wear & Crack Inspection

Thorough visual and ultrasonic inspection for defects

Hardness Verification

Rockwell hardness testing to verify material specifications

Dimensional Accuracy

Precision measurement with CMM and calibrated gauges

Regrinding & Polishing

Surface restoration services where applicable

Trial Fit / Test Support

Compatibility testing with your equipment

Refurbishment & Recoating

Optional reconditioning to extend tool life

Installation & Support

- Compatibility verification with your machine

- Export-grade packing for safe transport

- Tool setting & alignment guidance

- Maintenance & sharpening recommendations

Why Choose SASA IMPEX?

Your trusted partner for industrial tooling with decades of industry experience.

Trusted Importer

Established reputation for quality industrial tooling and machinery imports.

Cost-Effective Solutions

Access to quality pre-owned tooling at competitive prices.

Strong Sourcing Network

Extensive network spanning India and overseas suppliers.

Technical Support

Expert assistance before and after supply for optimal results.

Custom Solutions

Customized tooling solutions tailored to your specific requirements.