Injection MouldTooling Excellence

Precision-engineered injection moulds for mass production of plastic components. Single-cavity, multi-cavity, and custom moulds with unmatched accuracy and surface finish.

Key Advantages

Our injection moulds deliver superior performance across automotive, electrical, packaging, medical, and industrial sectors.

High Precision

Dimensional accuracy for consistent quality in every production cycle

Mass Production

Consistent repeatability for high-volume manufacturing needs

Excellent Finish

Superior surface finish with mirror, texture, or EDM options

Long Mould Life

Hardened steel construction for 300K–2M shot durability

Customizable

Tailored designs for any plastic component requirement

Cost-Effective

Optimized for high ROI in volume manufacturing

Industry Applications

Injection moulds are the backbone of modern plastic manufacturing, enabling precise, repeatable production across diverse sectors.

Automotive

Plastic parts & components

Electrical

Switchgear & housings

Packaging

Containers & caps

Medical

Disposables & housings

Household

Consumer plastic products

Industrial

Specialized components

25+

Years Experience

Types of Injection Moulds

We supply a comprehensive range of injection moulds to meet every manufacturing requirement.

Single Cavity Mould

One product per cycle – ideal for large or complex parts

Multi Cavity Mould

Multiple products per cycle – maximum production efficiency

Family Mould

Different parts in one mould – cost-effective for assemblies

Hot Runner Mould

Reduced material wastage – faster cycle times

Cold Runner Mould

Cost-effective tooling – simpler maintenance

Insert / Over-Mould

Metal + plastic integration – enhanced functionality

Product Gallery

Explore our range of injection moulds, manufacturing processes, and finished products.

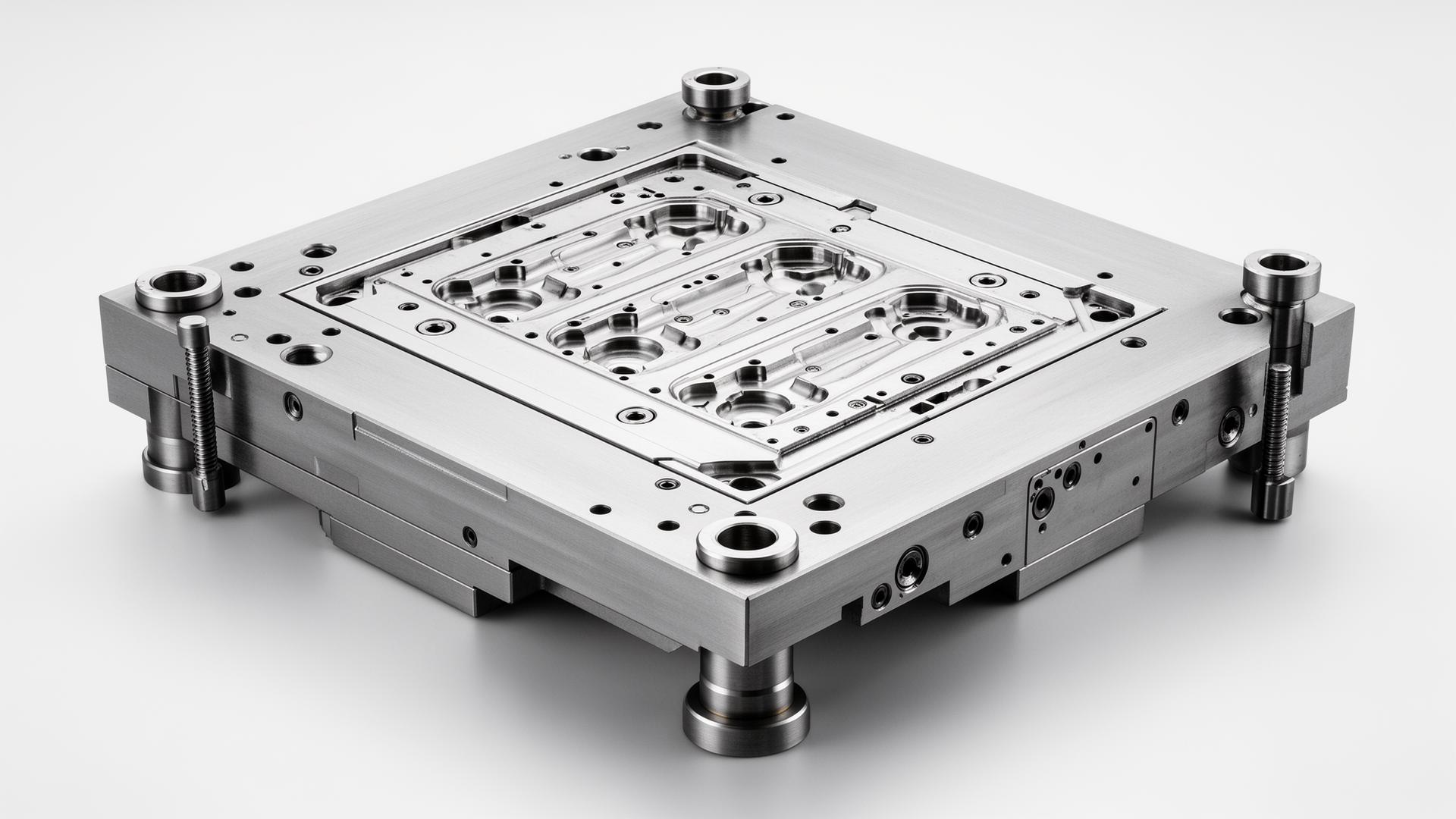

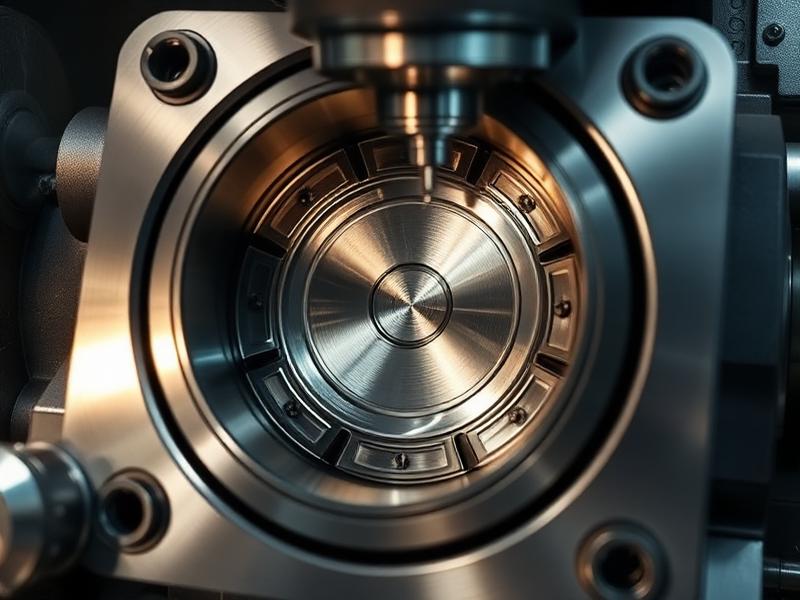

Precision Injection Mould

High-precision single-cavity injection mould tooling

Precision Injection Mould

High-precision single-cavity injection mould tooling

Precision Injection Mould

High-precision single-cavity injection mould tooling

Precision Injection Mould

High-precision single-cavity injection mould tooling

Precision Injection Mould

High-precision single-cavity injection mould tooling

Precision Injection Mould

High-precision single-cavity injection mould tooling

Precision Injection Mould

High-precision single-cavity injection mould tooling

Precision Injection Mould

High-precision single-cavity injection mould tooling

Technical Specifications

Detailed specifications vary based on product design and mould size. Here are our typical ranges.

| Parameter | Specification |

|---|---|

| Mould Type | Plastic Injection Mould |

| Cavity Options | 1 – 64 cavities |

| Mould Base | LKM / HASCO / DME |

| Mould Life | 300,000 – 2,000,000 shots |

| Runner Type | Hot runner / Cold runner |

| Ejection Type | Pin / Sleeve / Air / Plate |

| Parameter | Specification |

|---|---|

| Mould Steel | P20, H13, S136, 718 |

| Hardness | 28–52 HRC (depending on steel) |

| Surface Finish | Mirror / Texture / EDM |

| Cooling System | Water / Oil cooling |

| Guide System | Precision guide pillars & bushes |

Injection Mould Structure

An injection mould is a precision assembly of components working together to produce high-quality plastic parts.

The mould is mounted on an injection moulding machine, where molten plastic is injected, cooled, and ejected as finished parts.

Quality Assurance

For pre-owned injection moulds, SASA IMPEX provides comprehensive inspection and reconditioning support to ensure optimal performance.

Cavity & Core Inspection

Thorough wear assessment

Pressure Testing

Cooling channel verification

Ejector Verification

System functionality check

Trial Moulding

Sample production test

Reconditioning

Polishing & welding services

Installation Support

Setup & alignment assistance

Ready to Get Started?

Contact SASA IMPEX for competitive quotes on new and pre-owned injection moulds. Our team is ready to assist with your manufacturing needs.